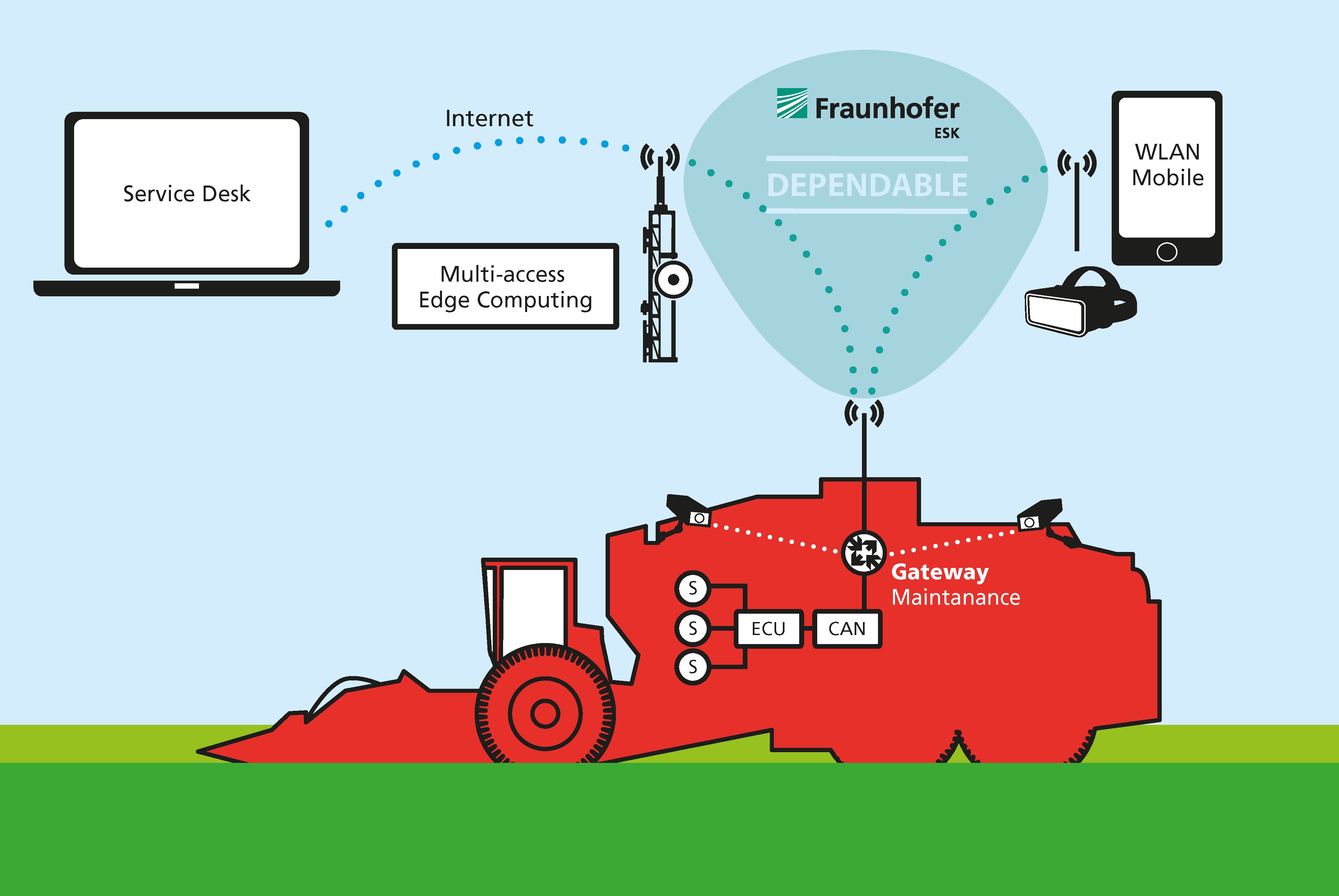

One of the challenges facing agriculture machine manufacturers such as Holmer and Horsch is the ability to offer fast and customer-oriented on-site service in their global markets. As part of the INVIA project, seven partners from industry and research are working on a solution for this problem. The goal is to design an innovative, cloud-based mobile assistance system for diagnosing and servicing complex agriculture machines and implement it in a prototype environment.

Resource-adaptive mobile assistance system for agriculture machines

Application scenarios: diagnostics, service, training

The project is examining three application scenarios:

1. Assisted diagnostics: Image- and video-based diagnostics support the operator of the machine during troubleshooting. After contacting the service desk, the operator is guided to the potential source of the problem with the help of audio, image and video information. The aim is to significantly improve service quality so that the service technician has the right replacement parts when he arrives.

2. Assisted service: An expert at the service desk supports the on-site service technician with augmented reality (AR) and connected diagnostic tools. This allows the service desk expert to manage multiple situations simultaneously, thus saving time and travel costs. An additional benefit is that on-site technicians improve their skills by working with the service desk experts and using the assistance systems.

3. Online-supported on-the-job operator training: While learning how to operate an agriculture machine requires extensive training, it's nearly impossible to demonstrate every function in different situations. For this reason, the INVIA project is also looking at expanding the training alternatives to include online-supported on-the-job training. Operators who find themselves in unfamiliar situations can receive support from a trainer at the company headquarters.

Cloud computing, mobile edge computing (MEC) and fog computing

Quality transmission of the audio, image and video information between the operator and manufacturer of the machine requires low latency. In addition, because mobile communication coverage varies widely in rural areas, the assistance system must be able to adapt to the local outdoor conditions.

INVIA relies on cloud computing, mobile edge computing (MEC) and fog computing. A so-called EDGE-ECU - or edge embedded control unit - is designed to form the core of the fog cloud if there is no connectivity to the mobile station or if the quality of the connection is low. That means the basic functionality of the assistance system is available even without connectivity to the central service system. The project team is also evaluating what advantages an integrated MEC component has as a replacement or supplement to centralized cloud services. Because of their close proximity to the machines, MEC components feature low latency and greater processing capacity, which makes it possible to implement AR or video services.

Fraunhofer Institute for Cognitive Systems IKS is making the following contributions

- Analysis and evaluation of the current research approaches in the area of cloud, mobile edge and fog computing

- Simulation of the adaptive behavior of the distributed assistance systems with dynamically-changing communication infrastructures

Fraunhofer Institute for Cognitive Systems IKS

Fraunhofer Institute for Cognitive Systems IKS