The advantage of predictive maintenance is that maintenance or service requirements are identified before the need actually arises. That saves time and more importantly reduces downtime for expensive machinery. In a joint project, equipment manufacturer Holmer, telecommunications manufacturer Huawei and the Fraunhofer Institute for Cognitive Systems IKS (former Fraunhofer ESK) succeeded in transferring the predictive maintenance method to a fleet of highly complex harvesting machines. To date, it has been used in conjunction with wind turbines and production systems.

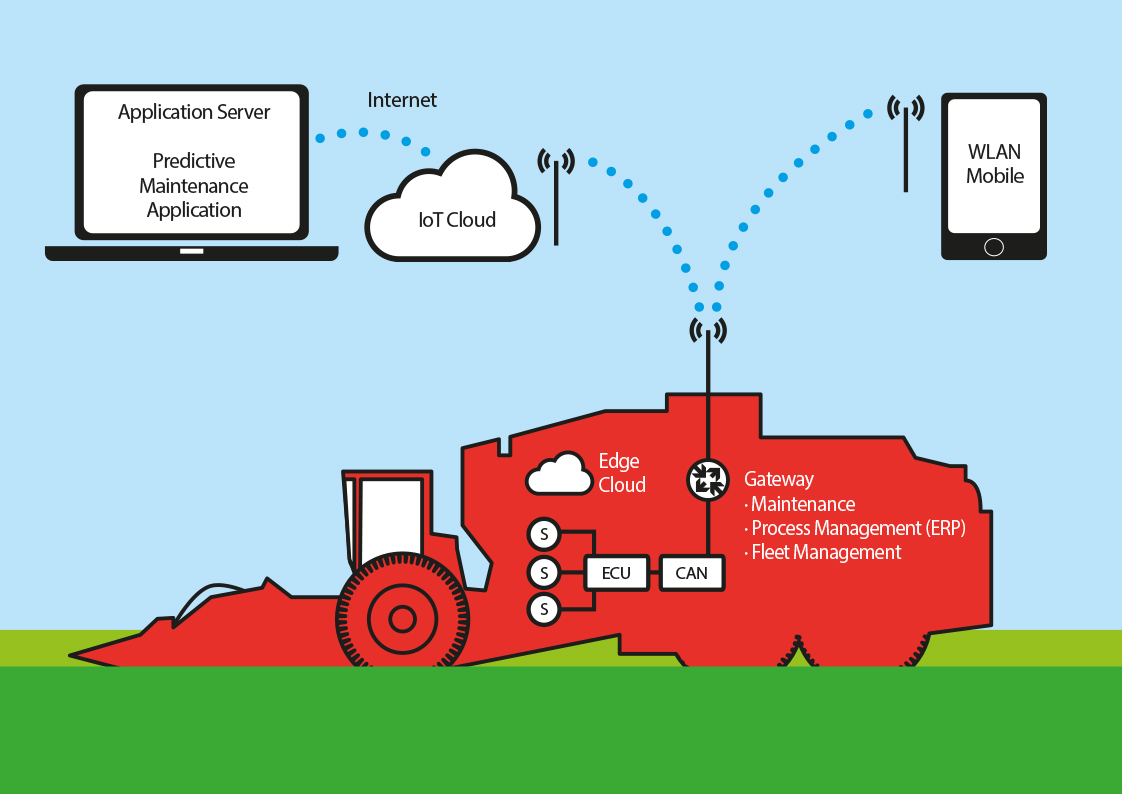

The technique involves the use of various sensors that monitor key areas of the machine, such as the drive train. The sensor data is transmitted via a mobile phone network to a central maintenance service in the cloud, which utilizes online analysis methods to detect irregularities and trigger an alarm far in advance. Rather than being restricted to individual machines, this approach is designed to support a globally operating fleet.

Fraunhofer Institute for Cognitive Systems IKS

Fraunhofer Institute for Cognitive Systems IKS