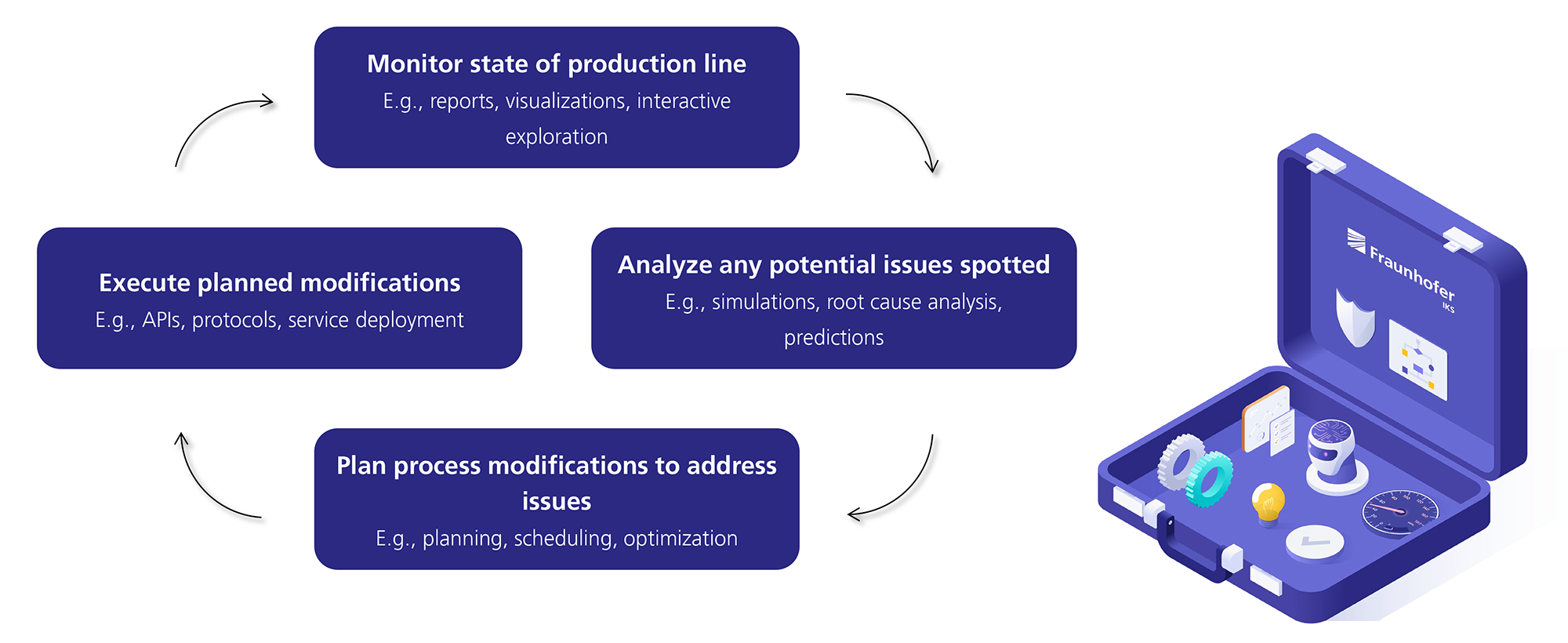

A modular approach to increase adaptability in manufacturing

With growing customer demands for product customization, smaller batches, and tighter delivery times, manufacturing companies need a production infrastructure that is as adaptable as possible. Fraunhofer IKS helps to bring these adaptation capabilities into production, using modular mechanisms that improve how resources respond to sudden changes. This increases the flexibility and resilience of the shop floor.

Fraunhofer Institute for Cognitive Systems IKS

Fraunhofer Institute for Cognitive Systems IKS